- Btech Basic Mechanical Engineering Workshop Manual Download

- Basic Mechanical Engineering Pdf

- Btech Basic Mechanical Engineering Workshop Manual Online

Note: This syllabus is common for Civil, ME, AE, ME (M), MME, AU, Mining, Petroleum, CEE, ME (Nanotech).

Mechanical Engineering all Subjects Multiple Choice Questions with Answers Practice Test Series: To download the e-books, pdf file of all Mechanical Engineering Subjects Practice Tests with Answers + Mechanical Technical Interview, go to E-books Corner. Civil engineering is a professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including works like roads, bridges, canals, dams, and buildings.

ME108ES/ME208ES: ENGINEERING WORKSHOP

B.Tech. I Year II Sem. L T/P/D C

0 0/3/0 2

Pre-requisites: Practical skill

Course Objectives:

Btech Basic Mechanical Engineering Workshop Manual Download

- To Study of different hand operated power tools, uses and their demonstration.

- To gain a good basic working knowledge required for the production of various engineering products.

- To provide hands on experience about use of different engineering materials, tools, equipments and processes those are common in the engineering field.

- To develop a right attitude, team working, precision and safety at work place.

- It explains the construction, function, use and application of different working tools, equipment and machines.

- To study commonly used carpentry joints.

- To have practical exposure to various welding and joining processes.

- Identify and use marking out tools, hand tools, measuring equipment and to work to prescribed tolerances.

Course Outcomes: At the end of the course, the student will be able to:

- Study and practice on machine tools and their operations

- Practice on manufacturing of components using workshop trades including pluming, fitting, carpentry, foundry, house wiring and welding.

- Identify and apply suitable tools for different trades of Engineering processes including drilling, material removing, measuring, chiseling.

- Apply basic electrical engineering knowledge for house wiring practice.

1. TRADES FOR EXERCISES:

At least two exercises from each trade:

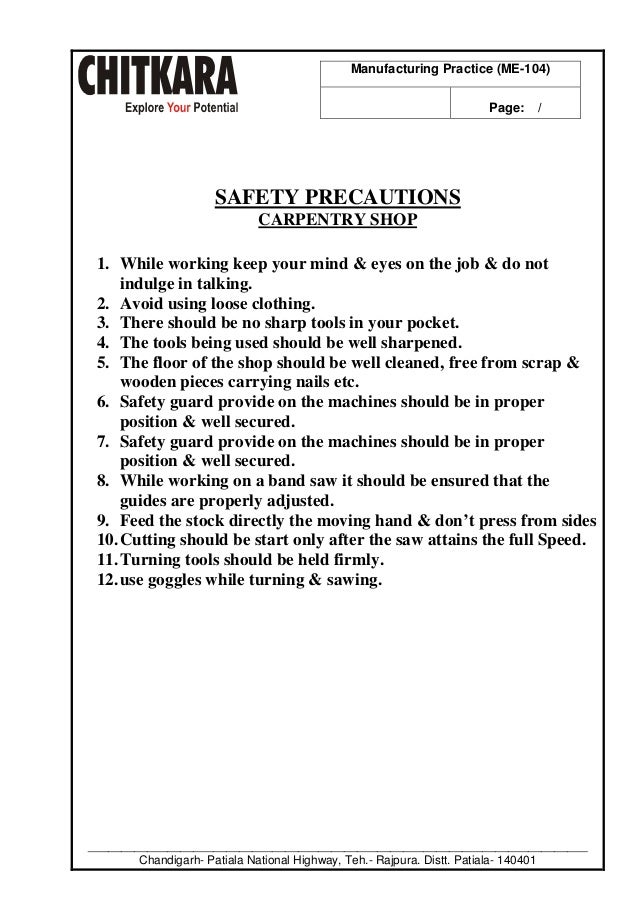

- Carpentry

- Fitting

- Tin-Smithy and Development of jobs carried out and soldering.

- Black Smithy

- House-wiring

- Foundry

- Welding

- Power tools in construction, wood working, electrical engineering and mechanical engineering.

2. TRADES FOR DEMONSTRATION & EXPOSURE:

- Plumbing, Machine Shop, Metal Cutting (Water Plasma)

Text Books:

- Workshop Practice /B. L. Juneja / Cengage

- Workshop Manual / K. Venugopal / Anuradha.

Reference Books:

- Work shop Manual - P. Kannaiah/ K. L. Narayana/ Scitech

- Workshop Manual / Venkat Reddy/ BSP

Note: This syllabus is common for EEE, ECE, CSE, EIE, BME, IT, ETE, ECM, ICE.

ENGINEERING WORKSHOP

B.Tech. I Year I Sem. L T/P/D C

Course Code: ME108ES/ME208ES 0 0/3/0 2

Pre-requisites: Practical skill

Course Objectives:

- To Study of different hand operated power tools, uses and their demonstration.

- To gain a good basic working knowledge required for the production of various engineering products.

- To provide hands on experience about use of different engineering materials, tools, equipments and processes those are common in the engineering field.

- To develop a right attitude, team working, precision and safety at work place.

- It explains the construction, function, use and application of different working tools, equipment and machines.

- To study commonly used carpentry joints.

- To have practical exposure to various welding and joining processes.

- Identify and use marking out tools, hand tools, measuring equipment and to work to prescribed tolerances.

2. TRADES FOR DEMONSTRATION & EXPOSURE:

- Plumbing, Machine Shop, Metal Cutting (Water Plasma)

Text Books:

- Workshop Practice /B. L. Juneja / Cengage

- Workshop Manual / K. Venugopal / Anuradha.

Reference Books:

- Work shop Manual - P. Kannaiah/ K. L. Narayana/ Scitech

- Workshop Manual / Venkat Reddy/ BSP

Note: This syllabus is common for EEE, ECE, CSE, EIE, BME, IT, ETE, ECM, ICE.

ENGINEERING WORKSHOP

B.Tech. I Year I Sem. L T/P/D C

Course Code: ME108ES/ME208ES 0 0/3/0 2

Pre-requisites: Practical skill

Course Objectives:

- To Study of different hand operated power tools, uses and their demonstration.

- To gain a good basic working knowledge required for the production of various engineering products.

- To provide hands on experience about use of different engineering materials, tools, equipments and processes those are common in the engineering field.

- To develop a right attitude, team working, precision and safety at work place.

- It explains the construction, function, use and application of different working tools, equipment and machines.

- To study commonly used carpentry joints.

- To have practical exposure to various welding and joining processes.

- Identify and use marking out tools, hand tools, measuring equipment and to work to prescribed tolerances.

Course Outcomes: At the end of the course, the student will be able to:

- Study and practice on machine tools and their operations

- Practice on manufacturing of components using workshop trades including pluming, fitting, carpentry, foundry, house wiring and welding.

- Identify and apply suitable tools for different trades of Engineering processes including drilling, material removing, measuring, chiseling.

- Apply basic electrical engineering knowledge for house wiring practice.

1. TRADES FOR EXERCISES:

At least two exercises from each trade:

- Carpentry

- Fitting

- Tin-Smithy and Development of jobs carried out and soldering.

- Black Smithy

- House-wiring

- Foundry

- Welding

- Power tools in construction, wood working, electrical engineering and mechanical engineering.

Basic Mechanical Engineering Pdf

2. TRADES FOR DEMONSTRATION & EXPOSURE:

- Plumbing, Machine Shop, Metal Cutting (Water Plasma)

Text Books:

- Workshop Practice /B. L. Juneja / Cengage

- Workshop Manual / K. Venugopal / Anuradha.

Reference Books:

- Work shop Manual - P. Kannaiah/ K. L. Narayana/ Scitech

- Workshop Manual / Venkat Reddy/ BSP

1ST Year B.TECH/B.E

(For All Branches)

List of Subject:

ELECTRICAL

Three Phase power measurement using two watt-meters

Starting and Reversing speed of a DC shunt motor

Open circuit and short circuit test of a single phase transformer

Determination of the magnetization characteristics (O.C.C) of a DC shunt Generator

Calibration of DC Ammeter and DC Voltmeter

Speed control of DC Shunt Motor.

MECHANICAL WORKSHOP

Preparing a work piece as per given drawing involving measuring drilling, reaming and tapping operation from a given Mild steel (MS) plate.

Preparing a wooden pattern for casting

Preparing a sand mould with the pattern for casting an aluminium block

Preparing a rectangular tray from a metallic sheet

Preparing a joint through Spot Welding between two sheets

Preparing a square Butt joint through Metal Arc Welding on flat plates

Preparing a cylindrical job as per given diagram by different operations in Lathe machine tool like Step Turning, Grooving, Chamfering and Threading

Btech Basic Mechanical Engineering Workshop Manual Online

Preparing a work piece as per given drawing involving measuring, sawing, filing operation from a given Mild steel (MS) plate.

ELECTRONICS

Familarization of electronic component – Transistor

Familarization of electronic component – Capacitor

Familarization of electronic component – Diode

Familization with power supply and multimeter

Study forward characterister of p-n junction diode

Familiarization with CRO and Function Generator Naruto shippuden all episodes dubbed free.

Familiarization of Basic Components – Resistor

Familiarization of Breadboard

Study of input characteristics and output characteristics of BJT in CB configuration

Study of transfer characteristics and output characteristics of Junction Field Effect Transistor (JFET)

Study of transfer characteristics and output characteristics of Metal Oxide Semiconductor Field Effect Transistor (MOSFET)

Characterization of Op-Amp

Study of different OPAMP circuits like Non-Inverting, Inverting amplifier, Adder & Substractor

Study of Logic Gates and realization of Boolean functions using Logic Gates

Introduction of common emitter amplifier

CHEMISTRY

Viscosity of Solutions Determination of percentage composition of sugar solution from Viscosity using Ostwald Viscometer.

Determination of the strength of a given hydrochloric acid solution against a standard sodium hydroxide solution

Determination of the strength of a solution of hydrochloric acid by a standard solution of sodium hydroxide using Conductivity meter

To determine the calcium and magnesium hardness in a given Water sample separately

Determination of partition co-efficient of Acetic acid between n-butanol and water at room temperature

Estimation of Fe (II) in Mohr's salt solution using standard KMnO4 solution via Redox titration

PHYSICS

Determine the Co-efficient of Viscosity by Poiseull's Capillary Flow method

Determination of modulus of rigidity of a wire by statically method using horizontal pattern of apparatus

Determination of young's modulus by flexural method.

Dermine the wavelength of the incident light by Newton's ring method

Determine the wavelength of unknown light by laser diffraction method

Determination of the Band-Gap of the semiconductor using the four probe method

Determination of Planck's Constant By Photo- Electric Effect

Determine the Rydberg constant by studying Hydrogen spectrum

Determination and Verification of Stefan's Constant

[Note:-If You Don't Find Your Lab-manuals Please Us. If you want to Provide Your Lab-Manuals to help others Please Now!]